Design for Manufacturability

Design for Manufacturability (DFM) is the engineering process of proactively designing a product in a way that simplifies production.

This method of engineering creates designs with fewer individual components by standardizing parts, maximizing the use of purchased components and creating modular designs with standard features. As a result, products are easier to fabricate and assemble in less time.

Companies that apply DFM can realize substantial benefits such as shortened development times, reductions in production costs as well as significant improvements in product quality, reliability and serviceability.

The Engineering Department at AAFI is available to work with your engineers and collaborate with your product development team to get the most out of your product design.

We can often make suggestions that will enhance your product and provide recommendations for the most efficient processes for manufacturing.

Our value added engineering services include:

- Early Supplier Involvement (ESI)

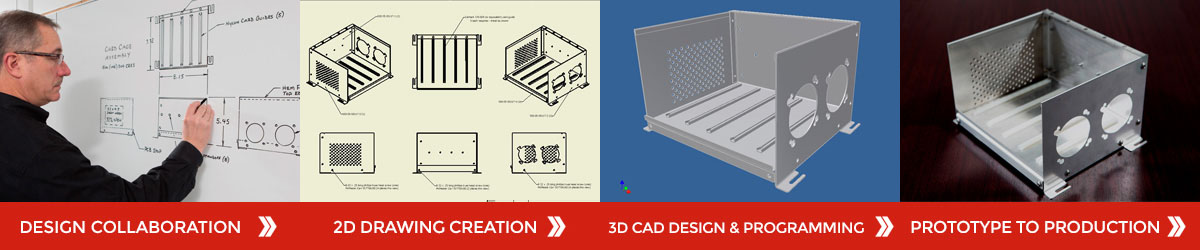

- Design collaboration

- Design assistance

- 3D modeling

- Reverse Engineering capabilities

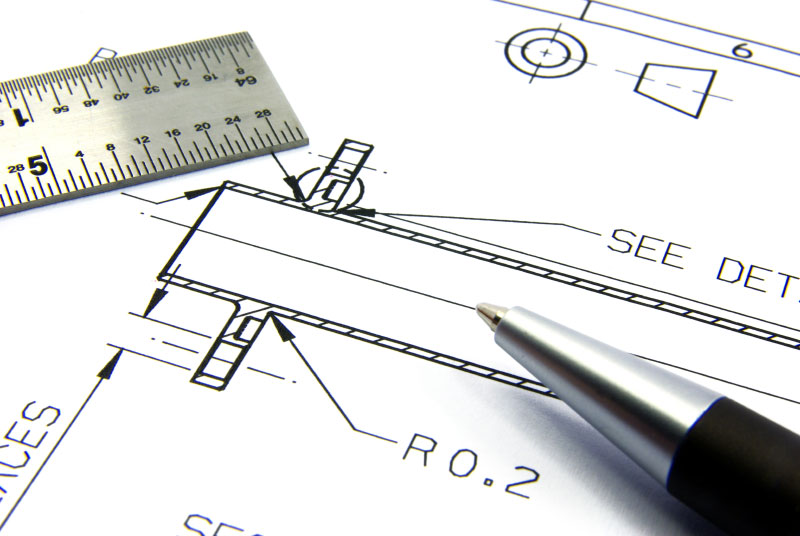

- Document and revision control

- Estimating

- Project planning

- CNC programming

Software and data exchange:

- ProEngineer (Pro-E) Wildfire

- AutoCAD Inventor

- Metalsoft FabriWin

- MIETrak (production control)

- DXF, DWG, IGES, STEP or Parasolid files for direct import into our CAD systems